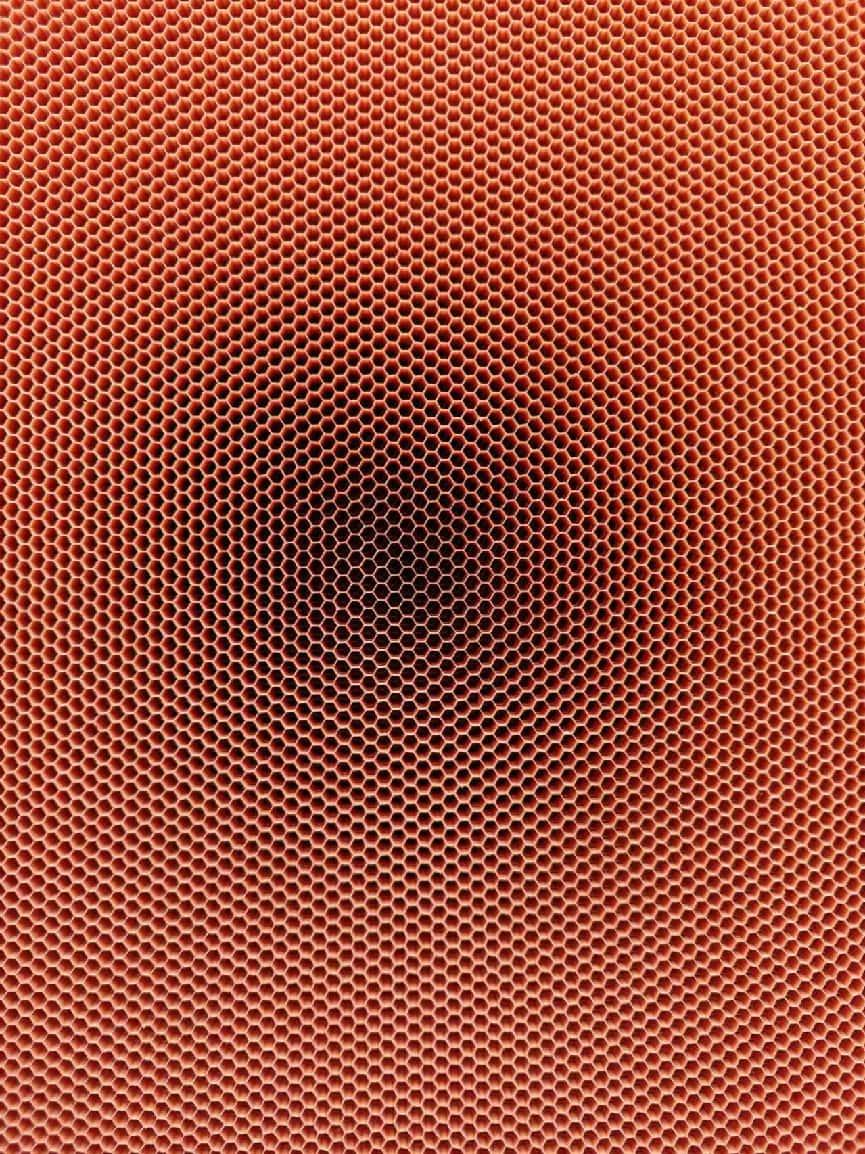

Common Materials Used in Non-metallic Honeycomb Composites

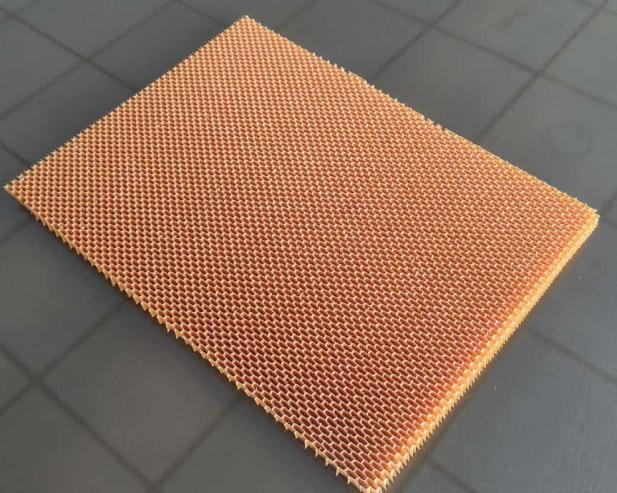

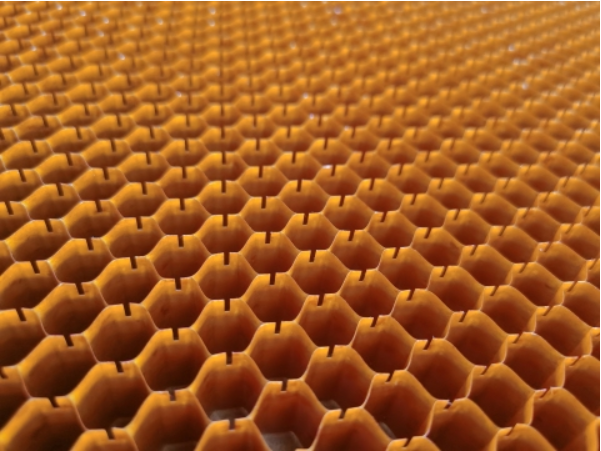

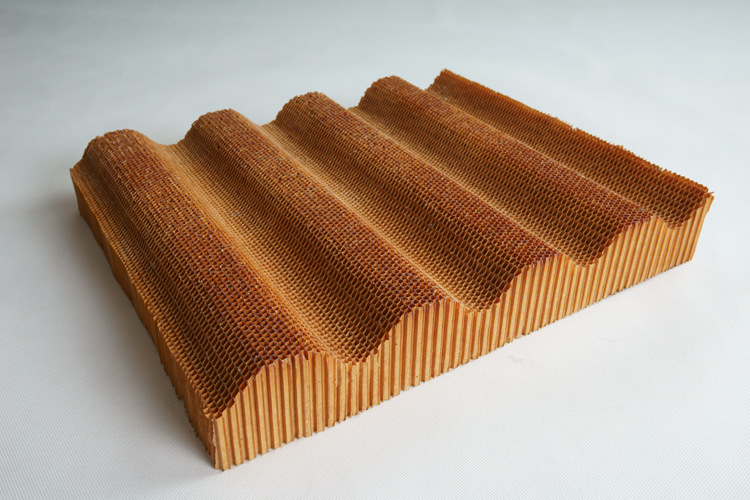

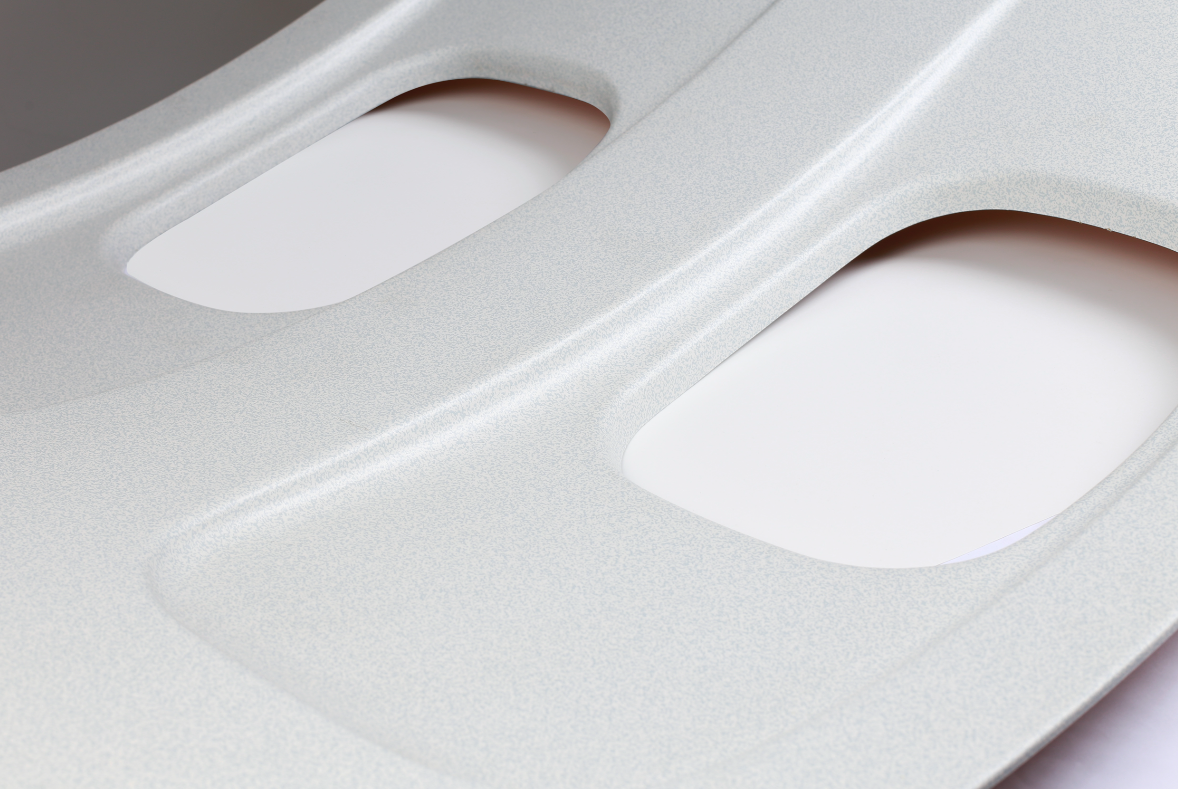

Non-metallic honeycomb composites are advanced materials widely appreciated for their strength, lightweight nature, and versatility across various industries. These composites are composed of a honeycomb core made from non-metallic materials bonded with face sheets—often made of fibers or plastics—to create a strong, durable, and lightweight panel or structure. Selecting the appropriate materials for the honeycomb core is critical, as it directly influences the mechanical properties, environmental resistance, and overall performance of the composite. Here are some of the most common materials used in non-metallic honeycomb composites.

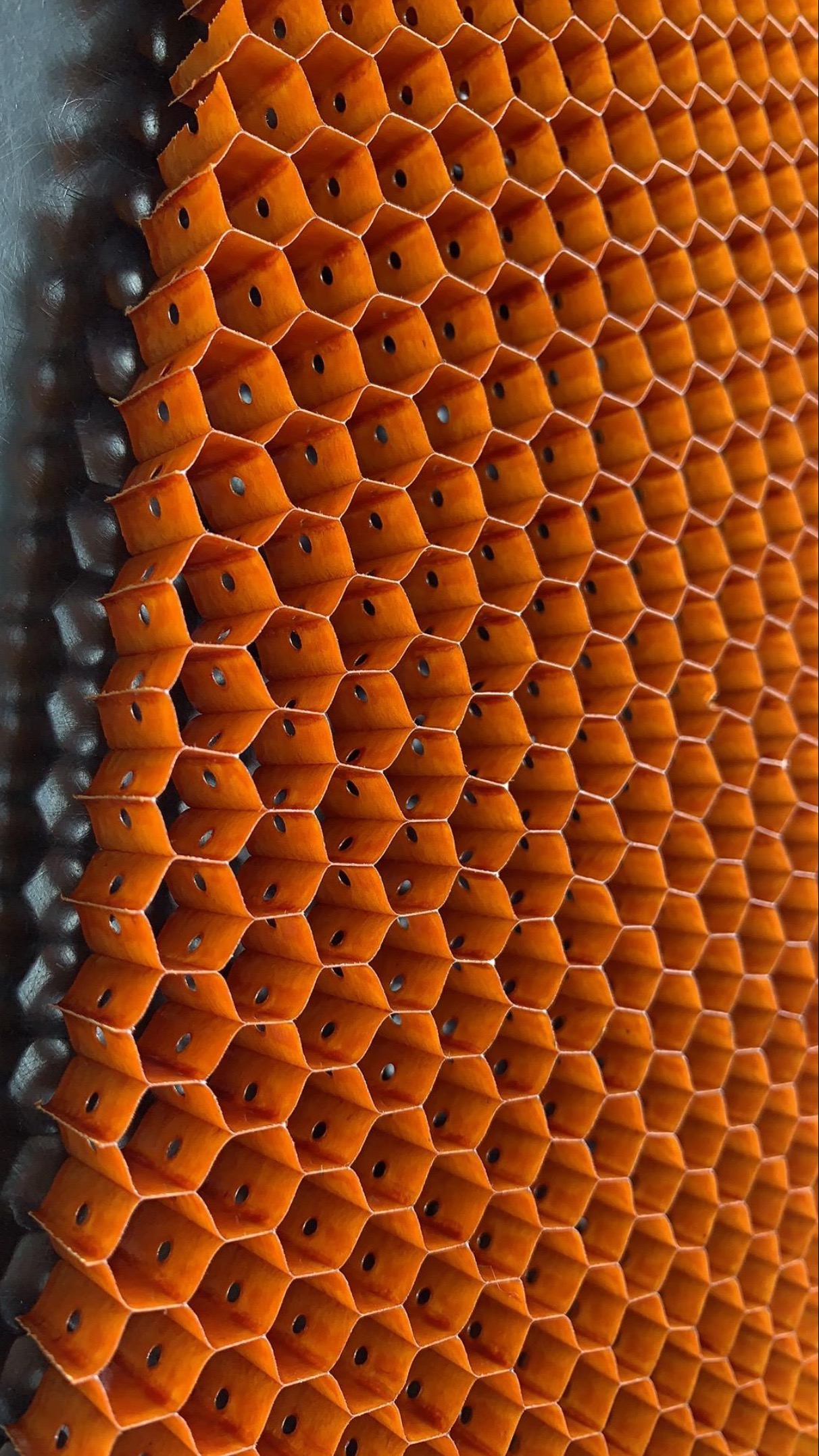

1. Polypropylene (PP)

Polypropylene is one of the most popular thermoplastics used to produce honeycomb cores. It offers excellent chemical resistance, good impact strength, and outstanding flexibility. Its lightweight nature makes it ideal for applications in the transportation industry, such as automotive interiors and packaging. Additionally, polypropylene honeycomb cores are recyclable, aligning with sustainable manufacturing goals.

2. Polycarbonate (PC)

Polycarbonate is a strong, transparent thermoplastic known for its high impact resistance and dimensional stability. When used as a honeycomb core material, it provides excellent load-bearing capabilities, especially in environments subjected to mechanical shocks. Its clarity and toughness make it suitable for applications like display panels, architectural glazings, and protective coverings.

3. Polyethylene (PE)

Polyethylene, particularly high-density polyethylene (HDPE), is valued for its exceptional chemical and moisture resistance. It is lightweight, flexible, and easy to process, making it a preferred choice for lightweight structural components, packaging inserts, and marine applications. PE honeycomb cores are also resistant to microbial growth, enhancing their durability.

4. Polypropylene-based Natural Fiber Composites

To enhance sustainability, natural fiber-reinforced plastics—such as hemp, jute, or kenaf reinforced polypropylene—are increasingly used as honeycomb core materials. These composites take advantage of renewable natural fibers, offering comparable mechanical properties to synthetic plastics but with improved environmental profiles. They are commonly used in furniture, interior panels, and eco-friendly packaging.

5. Paper and Cardboard

Paper honeycomb cores are among the most economical and environmentally friendly options. Made from recycled paper or cardboard, these cores are lightweight, biodegradable, and easy to manufacture. They are widely used in packaging, furniture panels, and temporary structures. Their performance can be enhanced through lamination or impregnation with adhesives to improve structural strength.

6. Fiberglass-reinforced Plastics

Fiberglass-reinforced plastic (FRP) honeycomb cores combine the strength of glass fibers with polymer matrices, offering high structural integrity and excellent chemical resistance. These materials are suitable for demanding applications such as marine, aerospace, and industrial equipment, where durability and lightweight properties are crucial.

7. Phenolic and Melamine Foams

In some specialized cases, phenolic and melamine foams are used as lightweight cores in composites. These foams provide excellent thermal insulation and fire resistance, making them ideal for use in building panels, refrigeration units, and other applications where fire safety is a concern.

Conclusion

The choice of material for non-metallic honeycomb cores largely depends on the specific application requirements, including mechanical strength, environmental resistance, weight, and cost. Materials such as polypropylene, polycarbonate, polyethylene, natural fiber composites, paper, and fiberglass-reinforced plastics each bring unique advantages that make them suitable for different industries—from aerospace to packaging to construction. As environmental considerations become increasingly important, the development and adoption of sustainable honeycomb core materials continue to grow, promising a future where high-performance composites are also eco-friendly.