Future Trends and Innovations in Non-metallic Honeycomb Technology

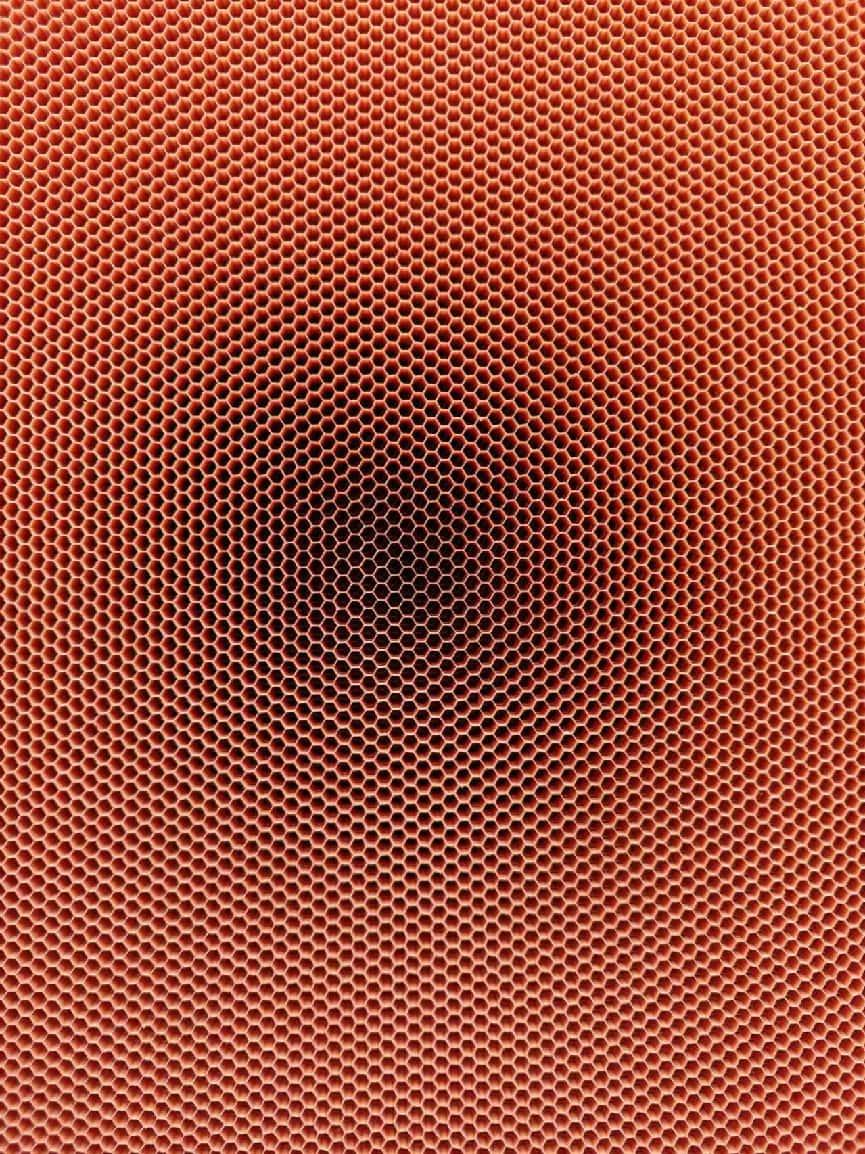

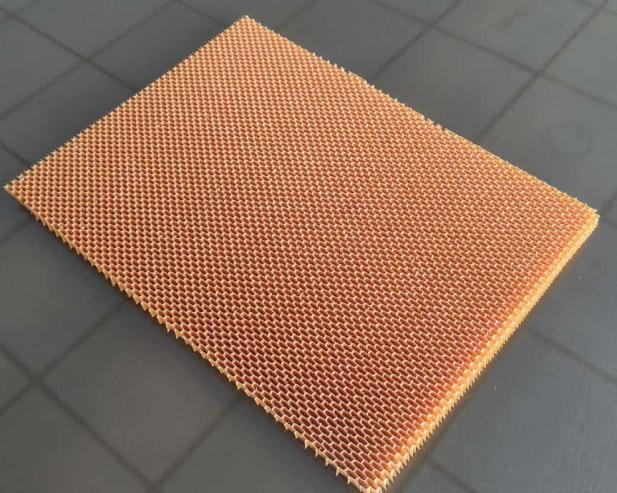

Non-metallic honeycomb structures have revolutionized industries ranging from aerospace to packaging, thanks to their outstanding strength-to-weight ratio, environmental durability, and versatility. As technology advances and global demands for sustainable and high-performance materials grow, the future of non-metallic honeycomb technology looks promising with several exciting trends and innovations on the horizon.

1. Emphasis on Sustainability and Eco-friendly Materials

One of the most significant future trends is the shift toward sustainable and biodegradable honeycomb core materials. Natural fibers like bamboo, jute, hemp, and recycled paper are increasingly being integrated into honeycomb structures to reduce environmental impact. Researchers are developing bio-based plastics and resins that can be combined with these natural fibers, creating composites that are not only high-performing but also recyclable and biodegradable. Such innovations align with the global push for eco-friendly manufacturing and circular economy principles.

2. Enhanced Mechanical Properties Through Material Innovation

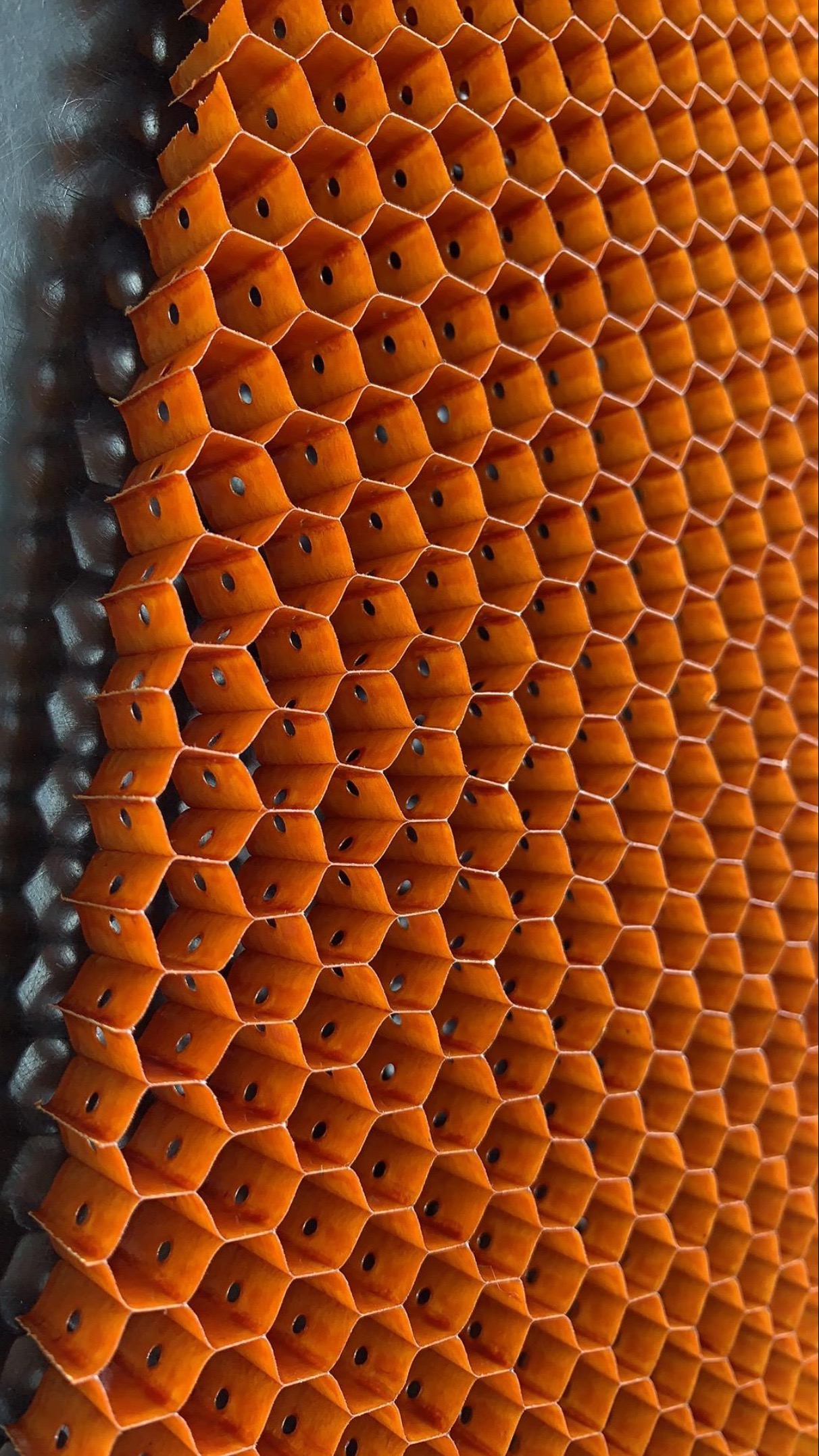

Advances in nanotechnology and resin chemistry are enabling the development of honeycomb cores with superior mechanical properties. Incorporating nanomaterials such as nanocellulose, graphene, or carbon nanotubes into non-metallic matrices can significantly improve strength, stiffness, and impact resistance. These enhancements open new avenues for lightweight structural components in aerospace, automotive, and defense industries, where every gram saved translates into performance gains.

3. Multifunctional and Hybrid Composites

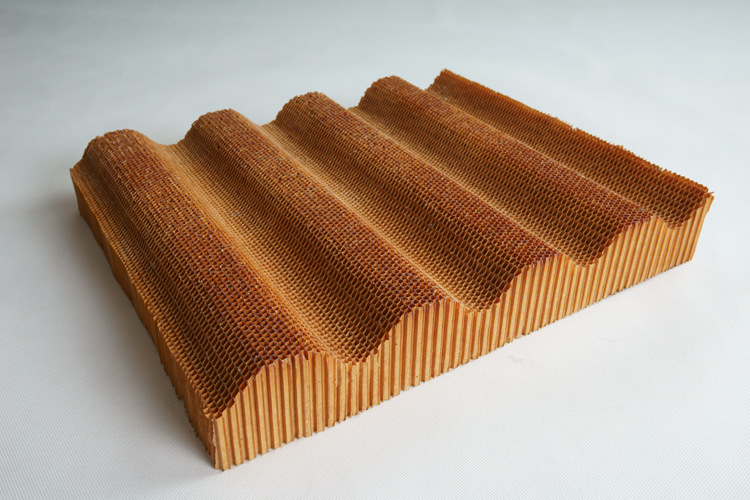

The future of honeycomb technology lies in creating multifunctional cores that provide additional benefits beyond structural support. For example, integrating insulating materials, fire-retardants, and antimicrobial agents within honeycomb cores can produce panels suitable for specialized environments like cleanrooms or marine applications. Furthermore, hybrid cores combining different materials—such as paper with polymer or natural fibers with synthetic resins—are being explored to optimize specific properties for tailored applications.

4. Additive Manufacturing and Customization

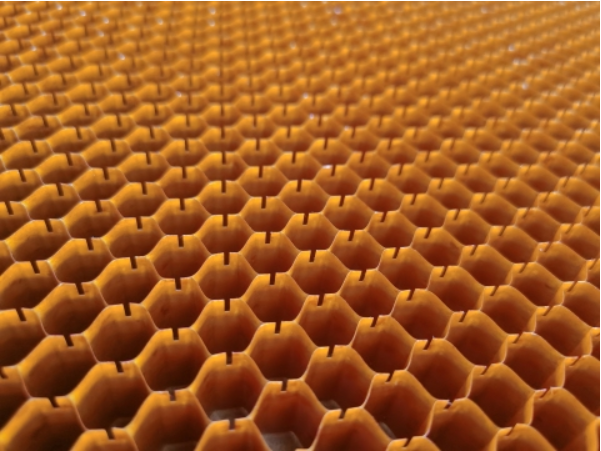

Additive manufacturing, or 3D printing, promises to revolutionize how honeycomb structures are designed and produced. Complex, bespoke honeycomb geometries can be created rapidly with minimal waste, allowing for highly customized solutions for specific performance needs. As 3D printing materials and technologies evolve, they will enable the production of intricate honeycomb cores with optimized cell sizes, shapes, and distributions, leading to improved strength, insulation, and weight reduction.

5. Improved Durability and Environmental Resistance

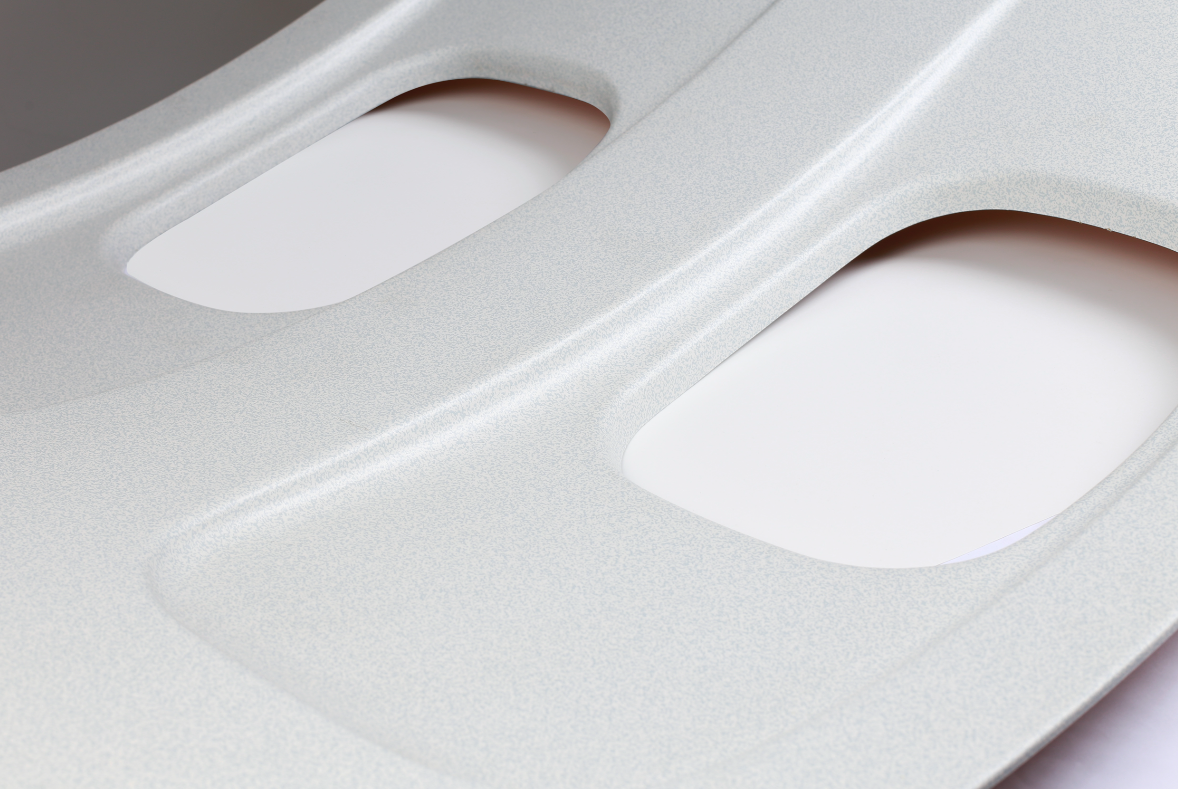

Innovations are also focusing on making non-metallic honeycombs more resistant to moisture, chemicals, UV radiation, and temperature fluctuations. Advanced coatings and surface treatments, along with the development of inherently resistant materials, will extend the longevity of honeycomb cores in harsh environments, broadening their applications in outdoor, marine, and industrial settings.

Conclusion

The future of non-metallic honeycomb technology is poised for a period of rapid innovation driven by environmental consciousness, material science advancements, and manufacturing innovations. Sustainable materials, nanotechnology enhancements, multifunctional composites, and additive manufacturing will shape the next generation of honeycomb structures, making them even more efficient, durable, and eco-friendly. As these trends unfold, non-metallic honeycomb cores will continue to play a critical role in enabling lightweight, high-strength, and sustainable solutions across various high-performance industries.