What Is Non-metallic Honeycomb and How Is It Used

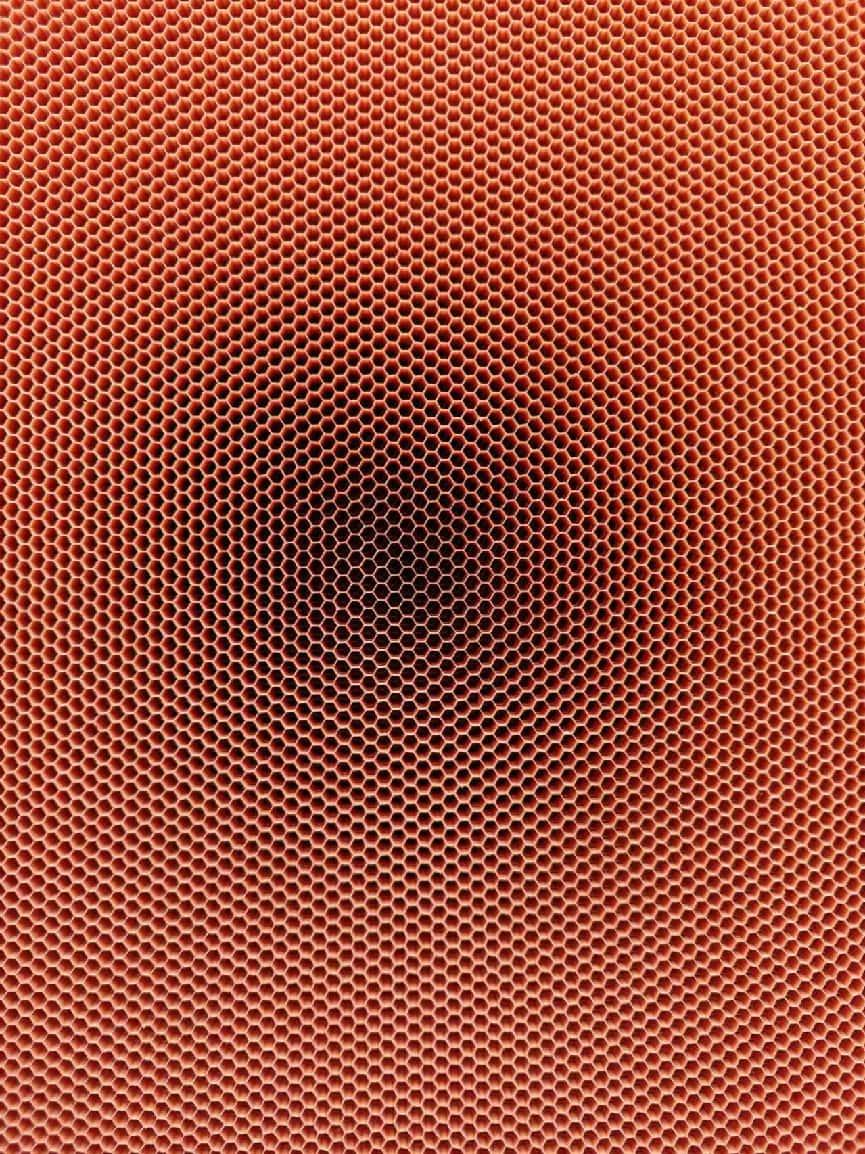

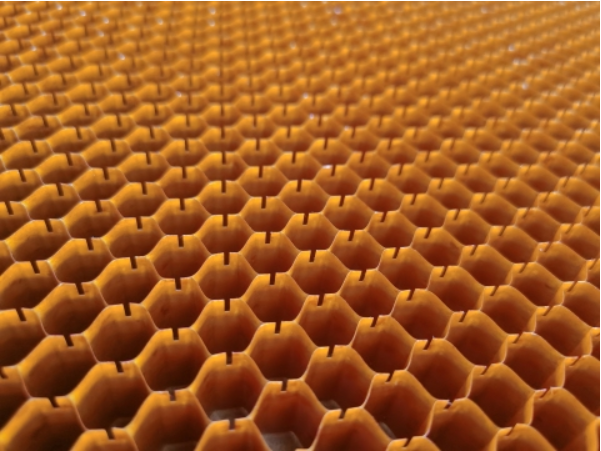

Non-metallic honeycomb structures are innovative materials that have gained significant attention across various industries due to their exceptional strength-to-weight ratio, versatility, and environmental benefits. Unlike traditional honeycomb composed of metals like aluminum or steel, non-metallic honeycombs are made from materials such as plastics, composites, or natural fibers. These structures mimic the familiar honeycomb pattern found in beehives, providing a lightweight yet robust core for a wide range of applications.

What Is Non-metallic Honeycomb?

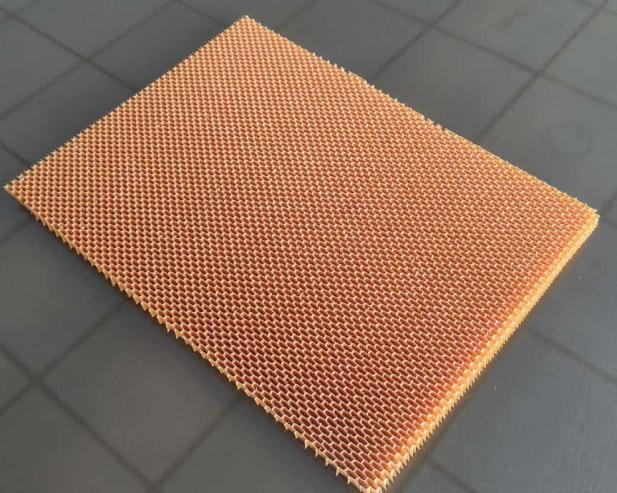

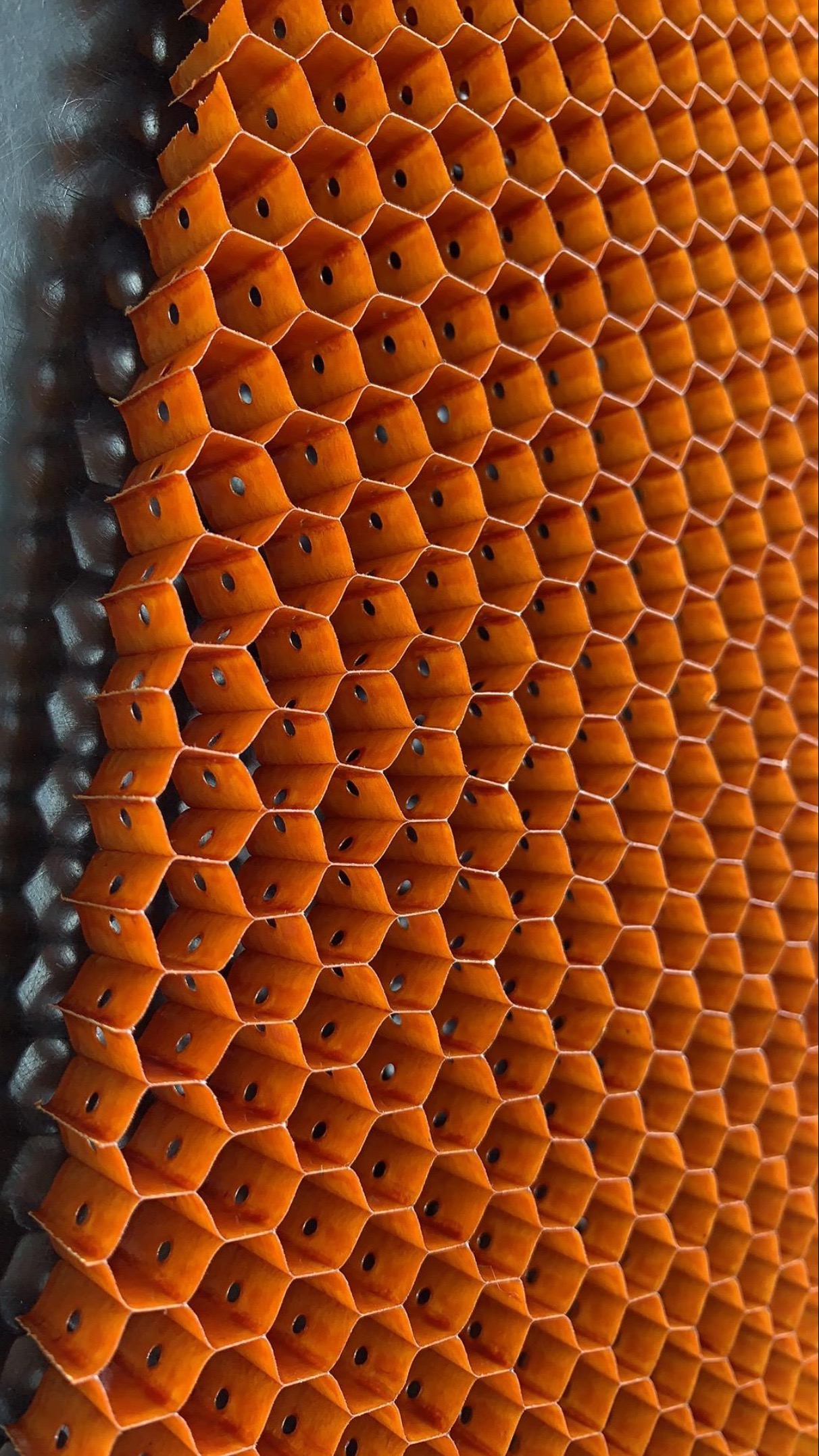

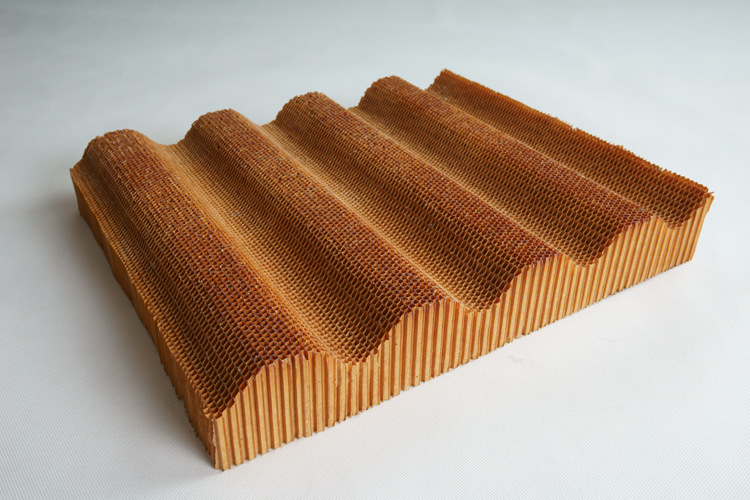

At its core, non-metallic honeycomb refers to a cellular structure made from non-metallic materials arranged in a hexagonal pattern. This geometry is inherently efficient in distributing loads and providing rigidity, making it ideal for various structural applications. Common materials used include polypropylene, polycarbonate, fiberglass-reinforced plastics, and natural fibers like bamboo or paper.

These materials are chosen for their properties such as being lightweight, corrosion-resistant, and capable of withstanding environmental stresses. The manufacturing process typically involves processes like extrusion, thermoplastic molding, or lamination, resulting in panels or cores suitable for different uses.

How Is It Used?

Non-metallic honeycomb structures are highly valued in several industries due to their desirable properties:

Aerospace and Automotive Industries:

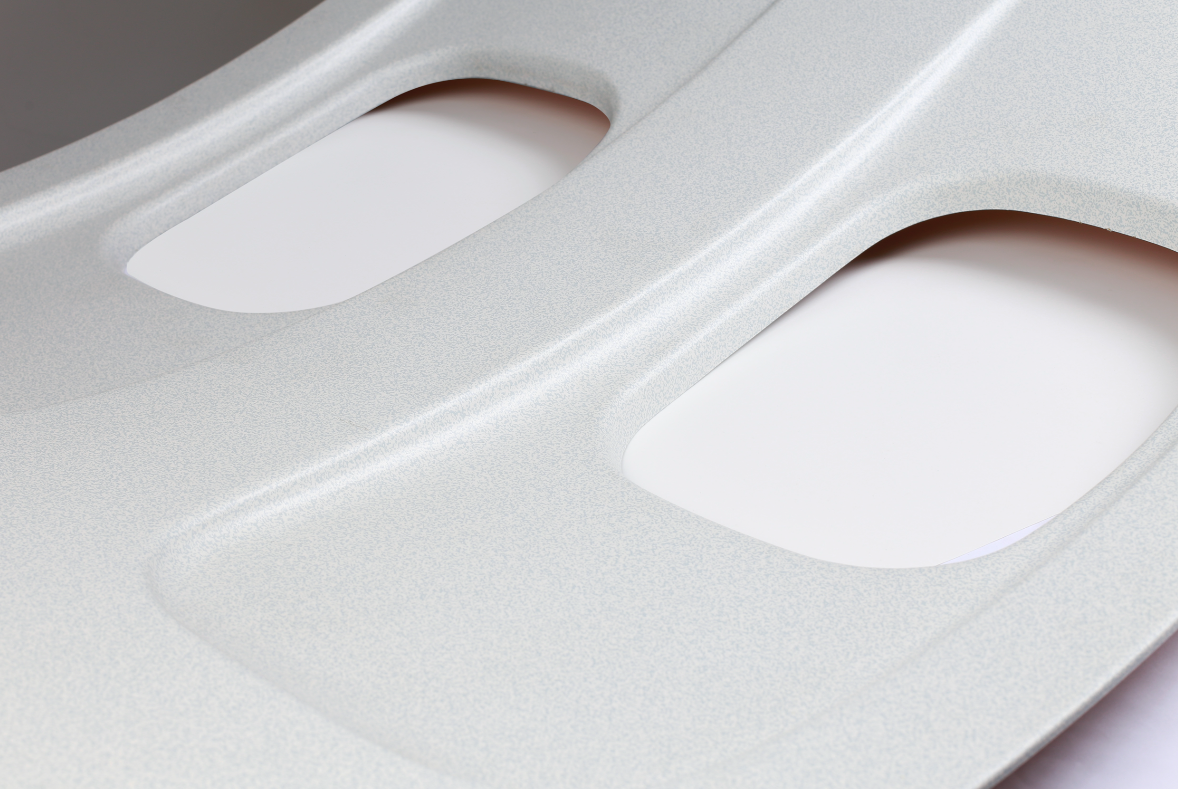

Lightweight honeycomb cores are used in aircraft and automobiles to reduce weight without sacrificing strength. They serve as core material in sandwich panels for fuselage, interior panels, and vehicle body parts, contributing to fuel efficiency and performance.Packaging and Shipping:

Its shock-absorbing qualities make non-metallic honeycomb an excellent choice for protective packaging. It cushions fragile items during transit and helps distribute external forces evenly.Construction and Architecture:

Non-metallic honeycomb panels are used as insulating layers, wall claddings, or decorative elements. Their lightweight nature simplifies installation while providing thermal and acoustic insulation.Composite Manufacturing:

As a core material in composite panels, non-metallic honeycomb enhances stiffness and durability, making it suitable for furniture, signage, and sporting equipment.Marine Applications:

Due to their corrosion resistance, these honeycomb structures are used in boat hulls, decking, and interior panels, extending the lifespan of marine vessels.

Advantages of Non-metallic Honeycomb

Compared to metal-based options, non-metallic honeycomb structures offer numerous benefits:

Lightweight: Significantly reduces overall weight, improving efficiency and handling.

Corrosion Resistance: Resistant to moisture, chemicals, and environmental degradation.

Cost-Effective: Often cheaper to produce and maintain.

Flexibility: Easily shaped and customized for specific applications.

Environmental Benefits: Many non-metallic materials are recyclable or made from sustainable sources.

Conclusion

Non-metallic honeycomb structures are transformative materials that blend engineering ingenuity with ecological consciousness. Their ability to deliver strength, lightness, and versatility makes them indispensable in modern manufacturing, transportation, and construction sectors. As technology advances, we can expect further innovations in non-metallic honeycomb materials, unlocking new possibilities for sustainable and efficient design solutions.